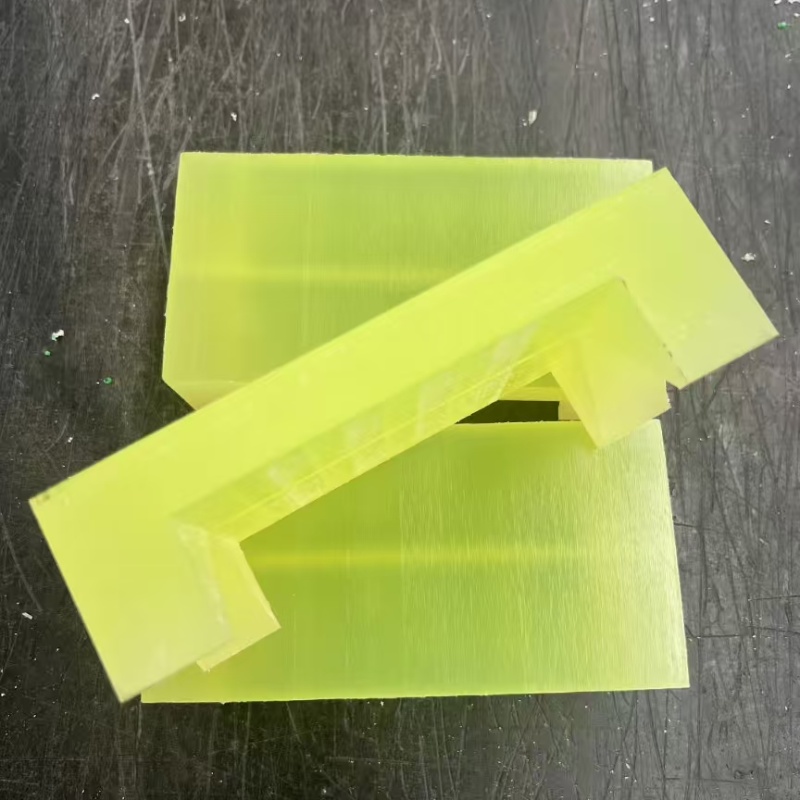

PU machined parts offer exceptional comprehensive properties: wear resistance significantly exceeds most rubber materials, being 3-8 times that of natural rubber; high load-bearing capacity and excellent elastic recovery effectively absorb impact energy; good resistance to oil, ozone, and radiation; broad hardness range allows customization from soft elasticity to rigid structures; high tear strength ensures long service life. Additionally, PU demonstrates good machinability, enabling precision manufacturing of complex structures. The material is odorless and tasteless, with some grades meeting food and medical standards, while modifications can enhance special properties like high-temperature resistance, hydrolysis resistance, or conductivity.

PU machined parts are widely used across various industries. In engineering machinery, they serve as buffer pads, seals, and hydraulic cylinder wipers for high-pressure applications. In material handling systems, they function as conveyor rollers and guides, leveraging their wear-resistant advantages. The automotive industry utilizes them for suspension system bump stops and shock absorption components requiring high elasticity. Printing and packaging machinery rollers and textile guide parts also extensively use PU. Furthermore, they are widely applied in medical equipment (e.g., wheelchair tires), sports equipment (e.g., pulley coatings), and mining machinery (e.g., screen linings), meeting various demanding operational needs with superior wear resistance and cushioning characteristics.