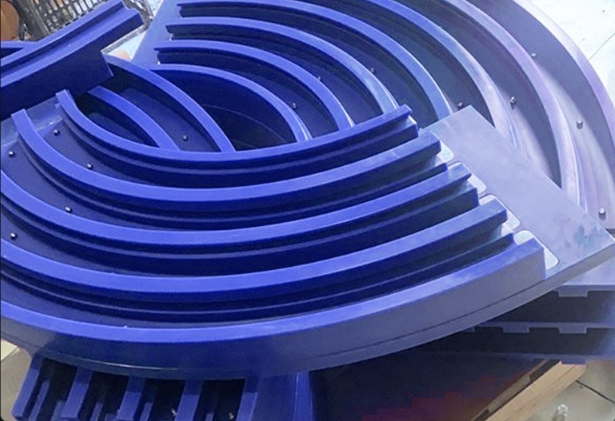

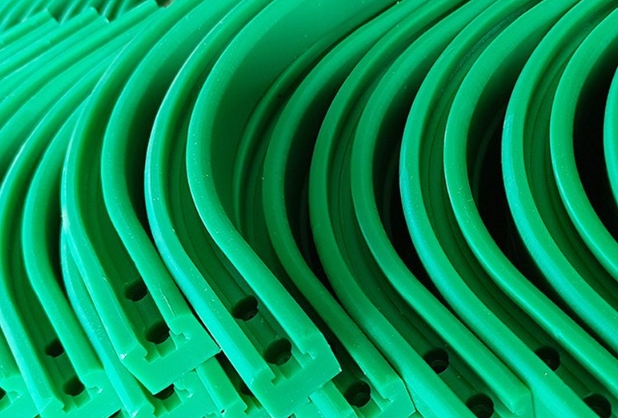

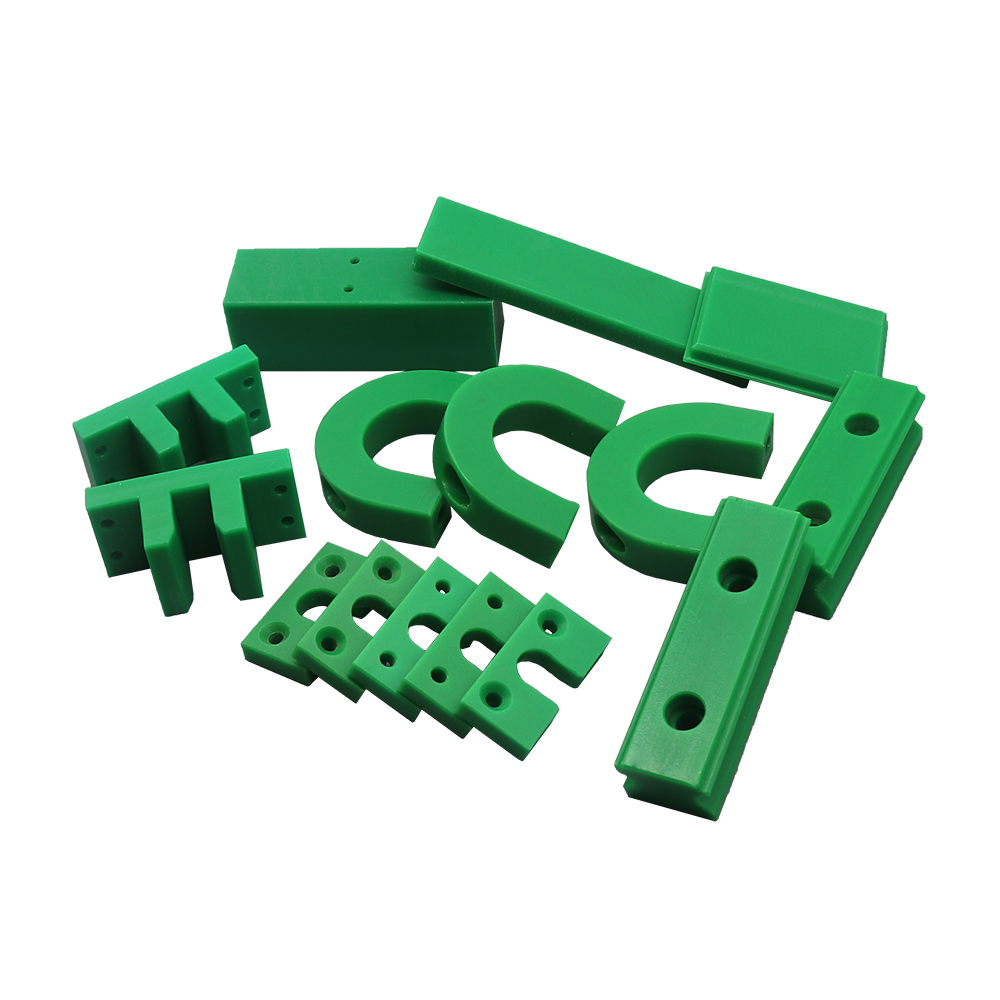

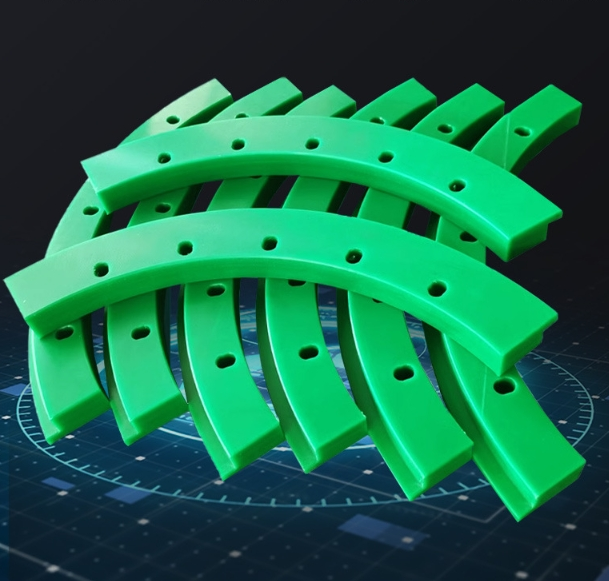

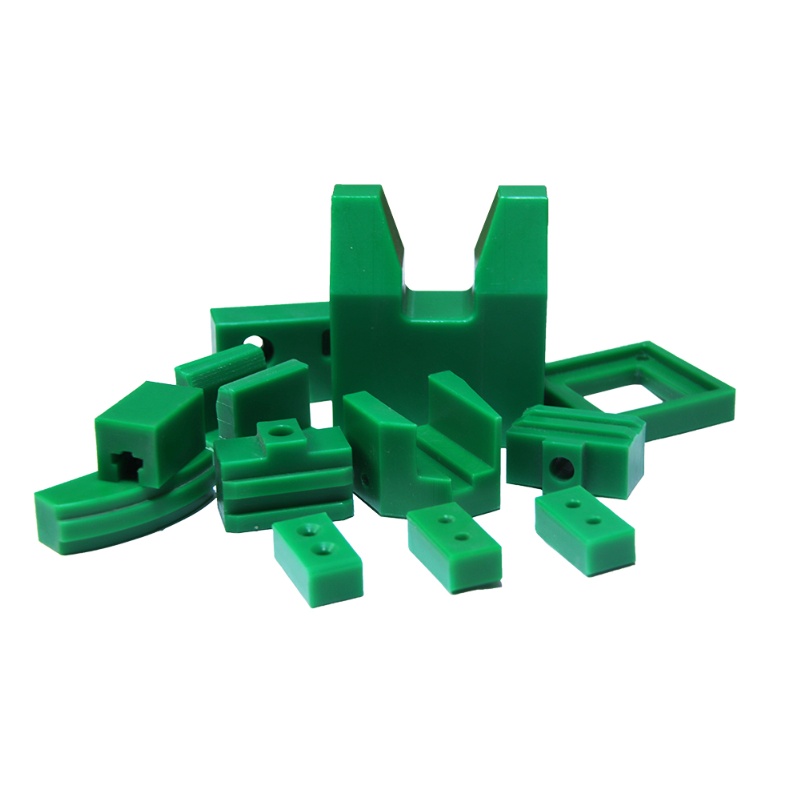

UHMWPE special-shaped parts offer exceptional characteristics: they possess the highest wear resistance among plastics, outperforming nylon and PTFE by several times and even surpassing carbon steel; their low friction coefficient provides self-lubrication, enabling operation in oil-free environments; high impact strength ensures toughness even at low temperatures; excellent chemical stability resists acids, alkalis, and organic solvents; low density makes them lightweight for easy handling and installation. Additional properties include non-adhesion, noise reduction, and moisture resistance. Being non-toxic and odorless, they meet hygiene standards for food and medical industries. These parts can be precision-machined or molded to meet tight tolerances and complex structures in a single piece, reducing assembly steps.

UHMWPE special-shaped parts are widely used across industries. In logistics and transportation, they serve as conveyor guides, chain guides, and shelf liners, reducing wear and noise. In food and pharmaceutical sectors, FDA-compliant parts are used in filling lines, packaging machine liners, and conveyor accessories. Their corrosion resistance makes them ideal for valve linings, pump components, and tank linings in chemical equipment. In mining machinery, high impact and wear resistance suit applications like screen plates, chute liners, and gears. Additionally, these parts are key components in textile machinery, agricultural equipment, sports gear, and even new energy battery production lines due to their superior performance.