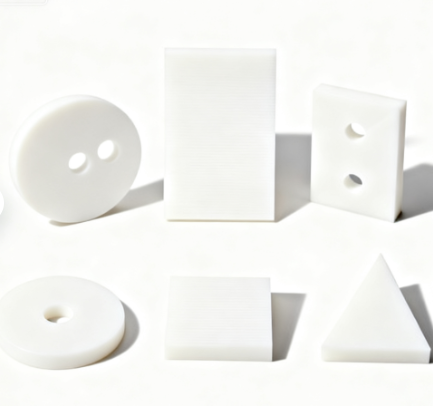

PTFE machined parts possess a unique set of properties: an extremely low coefficient of friction (approx. 0.04) provides superior self-lubrication for operation without external lubricants; outstanding chemical resistance withstands nearly all strong acids, alkalis, and solvents; an exceptionally wide operating temperature range with excellent thermal stability; superior electrical insulation properties, coupled with non-absorbency, non-adhesion, and non-toxicity. The material is flexible and highly resistant to aging. While its mechanical strength is moderate, adding fillers like glass fiber, graphite, or carbon fiber can significantly enhance wear resistance and dimensional stability for broader applications.

PTFE machined components are widely used in extreme or specialized conditions. In the chemical industry, they serve as valve linings, pump seals, and reactor linings, offering corrosion resistance and media purity. In semiconductors and electronics, they are used for wafer carriers, insulating spacers, and high-frequency circuit boards, ensuring cleanliness and insulation. The food and pharmaceutical sectors utilize them as conveyor guides and filling nozzle seals for their safety and non-toxicity. Automotive applications include fuel system seals and bearing bushings for their high-temperature and oil resistance. Furthermore, in aerospace, military equipment, and biomedical devices, PTFE parts are critical functional elements meeting stringent requirements in specialized environments.