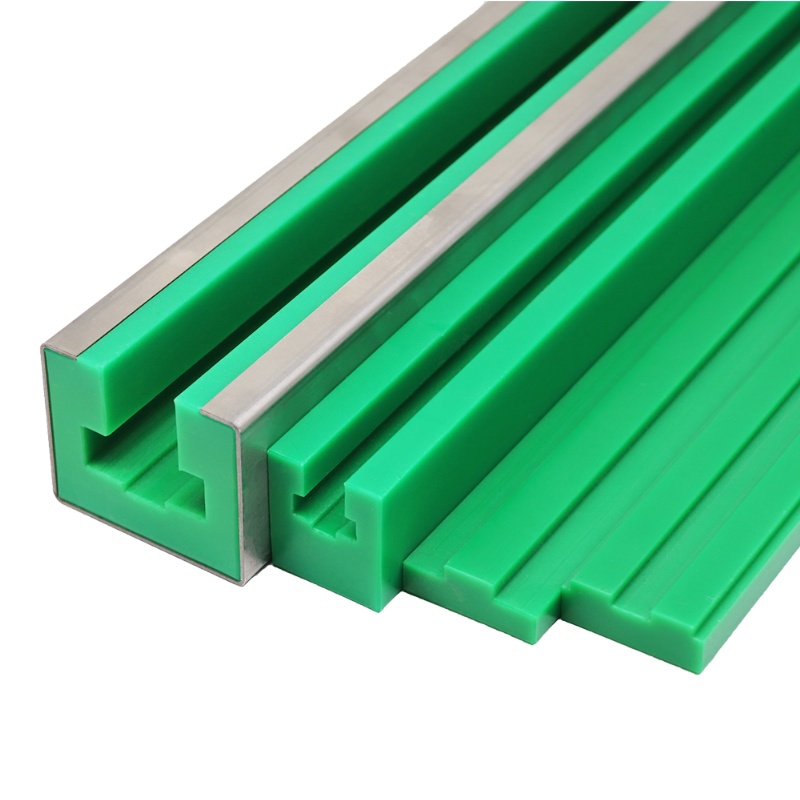

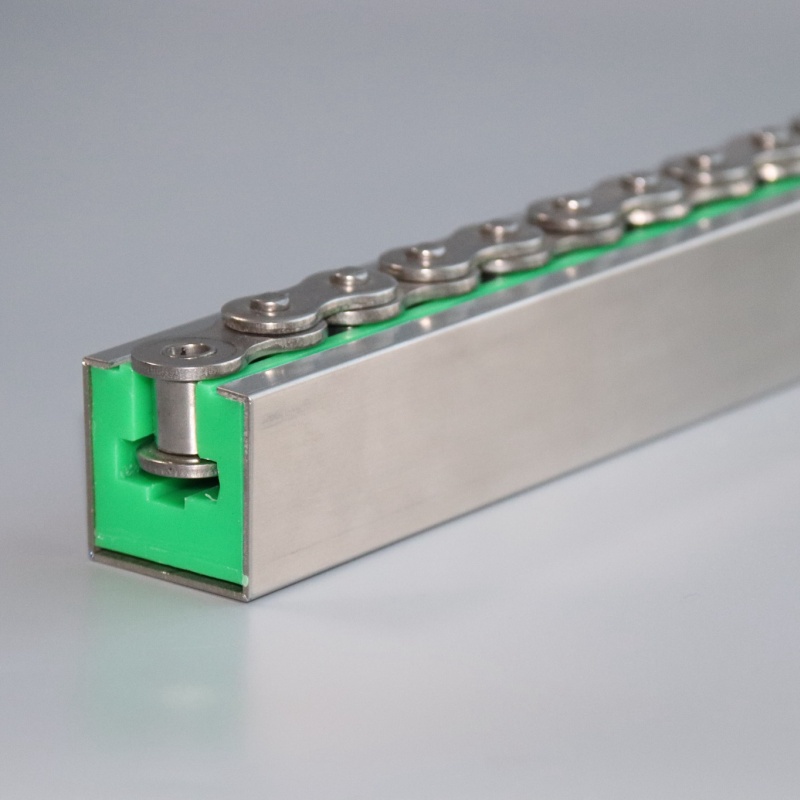

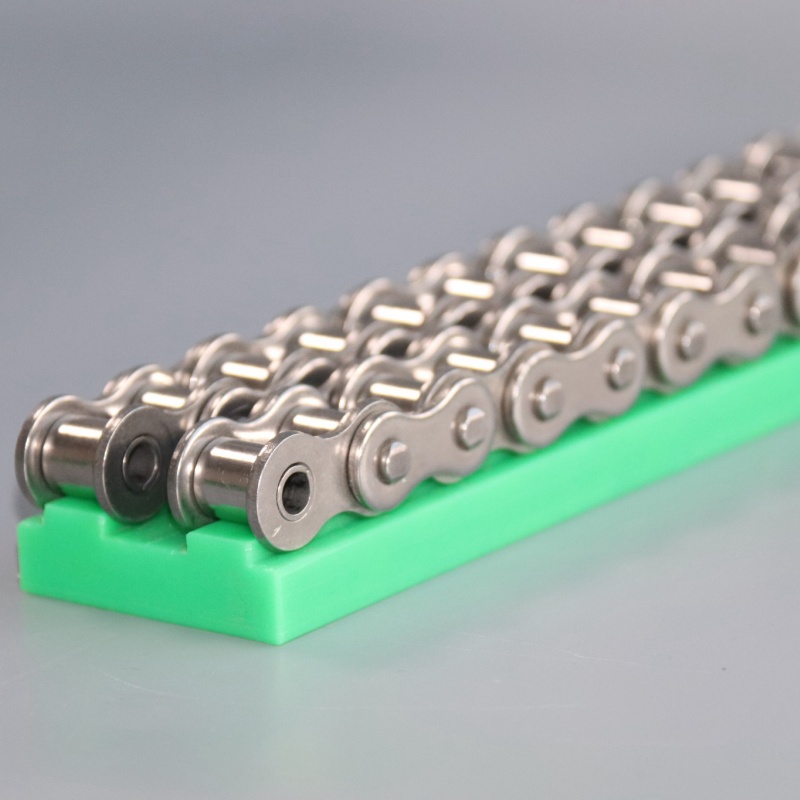

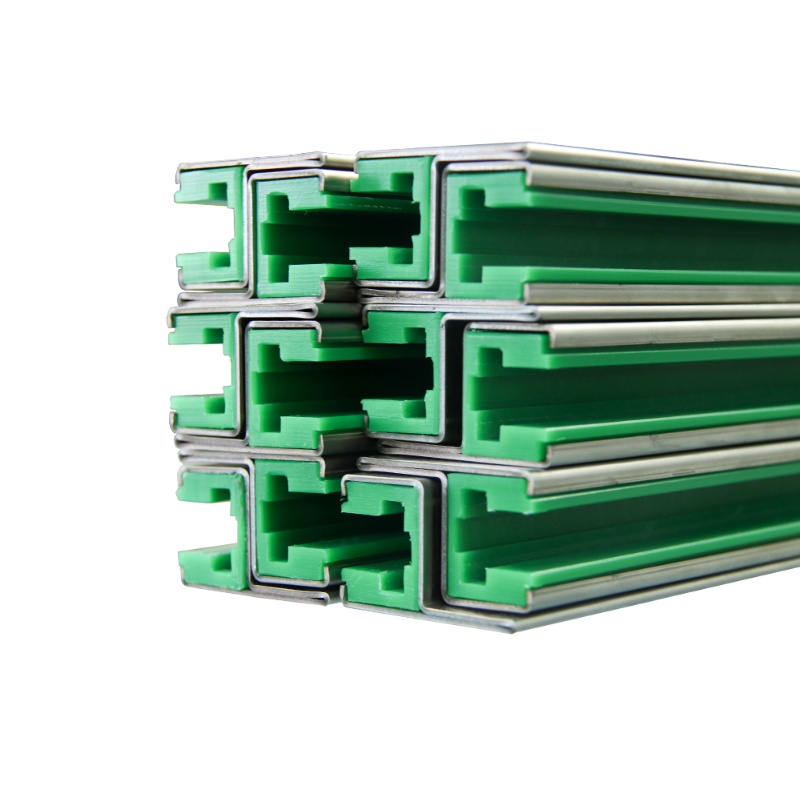

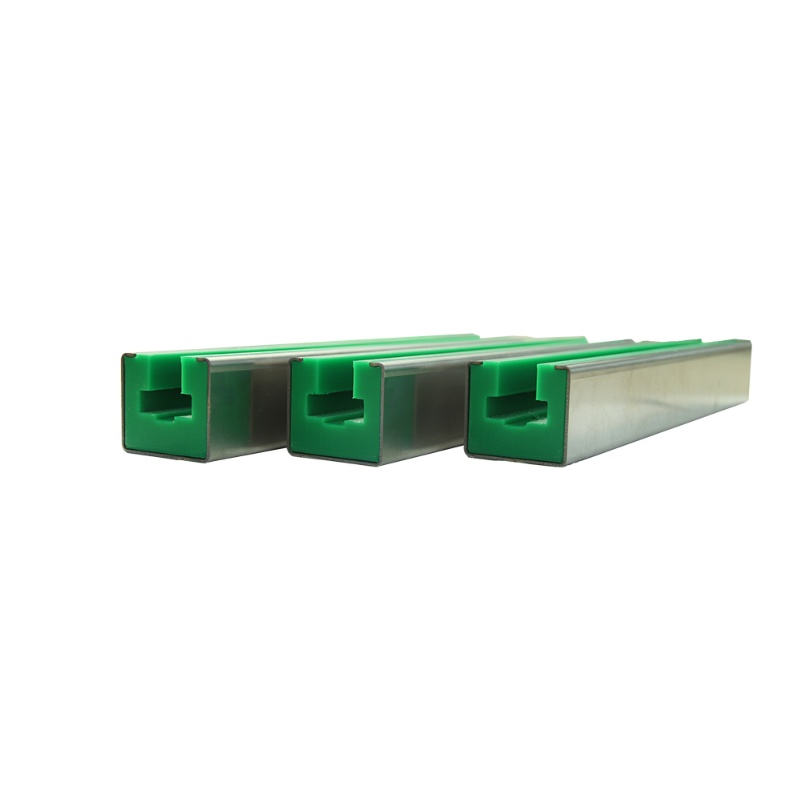

Chain guides offer several outstanding performance characteristics. A key feature is their low friction coefficient, which significantly reduces energy loss between the chain and the guide, thereby improving transmission efficiency and lowering energy consumption. Many guides are made from self-lubricating materials such as PTFE or UHMWPE, allowing operation with minimal or no lubrication and reducing maintenance needs. They also exhibit high wear resistance and impact strength, maintaining dimensional stability under long-term heavy loads and extending chain service life. Some models are resistant to chemical corrosion and static electricity, making them suitable for diverse working conditions. Structurally, most guides feature modular designs for easy installation and can be customized in size to fit various spatial and functional requirements.

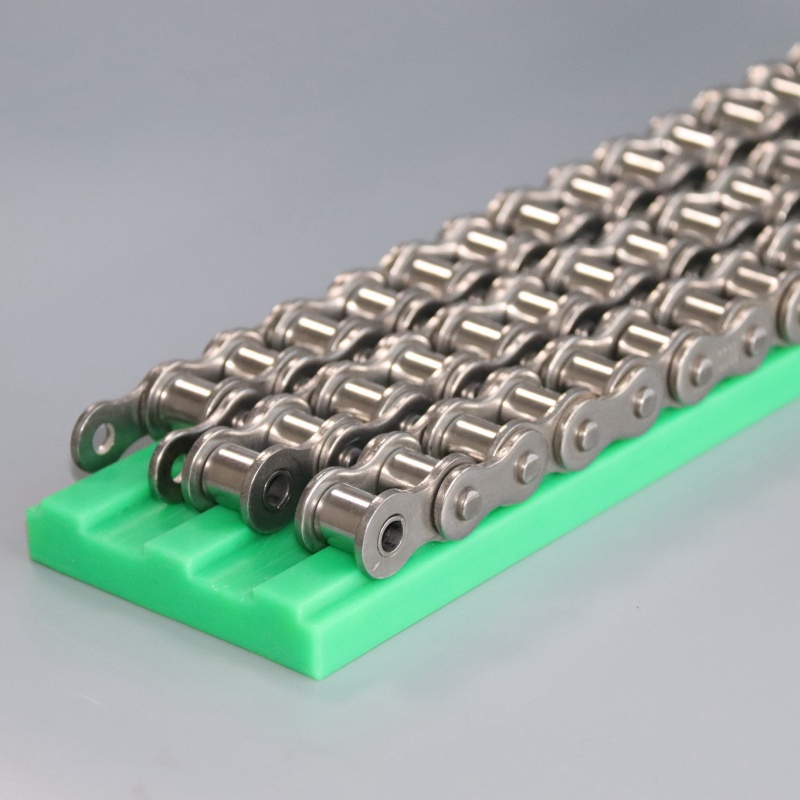

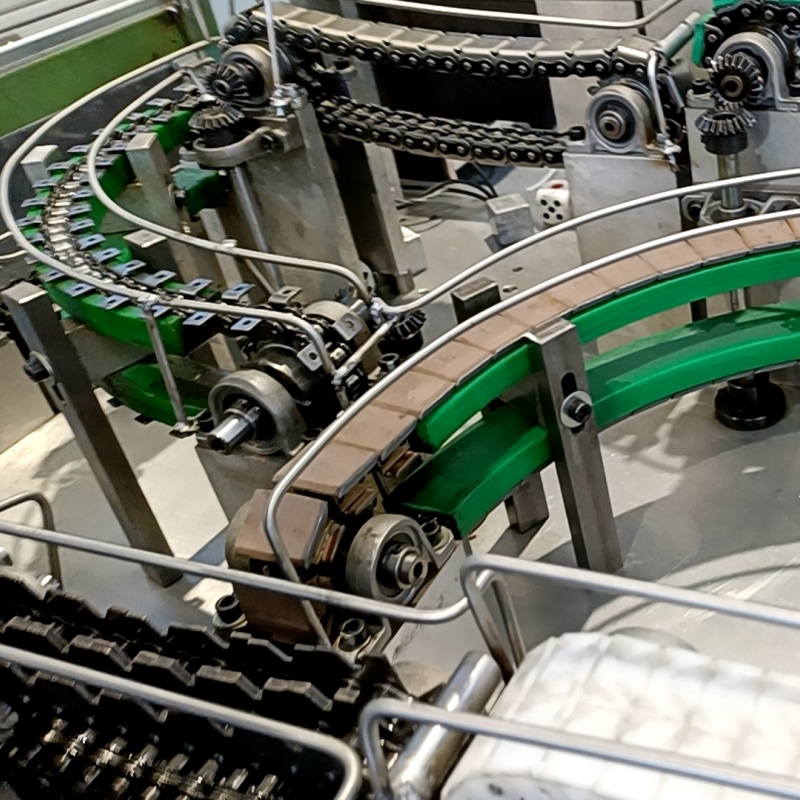

Chain guides are widely used in industrial applications that require high-precision chain transmission, including automated conveyor systems, packaging machinery, printing equipment, food processing lines, and automotive assembly lines. In conveyor systems, they ensure smooth and synchronized chain movement over long distances, preventing derailment or jamming. In clean environments such as electronics or pharmaceutical industries, non-metallic guides like UHMWPE are preferred due to their non-contaminating and corrosion-resistant properties. In heavy industries such as mining or metallurgy, MC nylon or metal-composite guides withstand extreme temperatures and heavy loads. With the advancement of smart manufacturing, chain guides are increasingly integrated into robotic drive units and intelligent logistics sorting systems, enhancing the automation level of overall equipment.

|  |

|  |