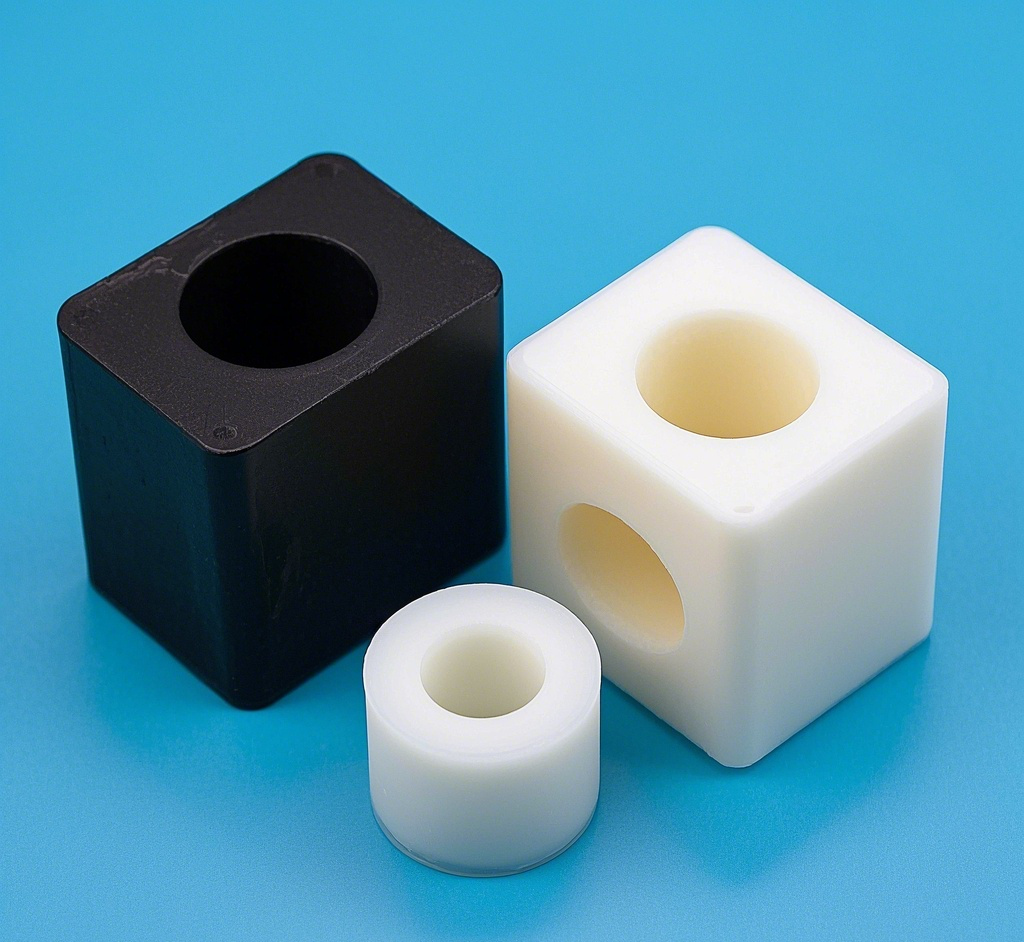

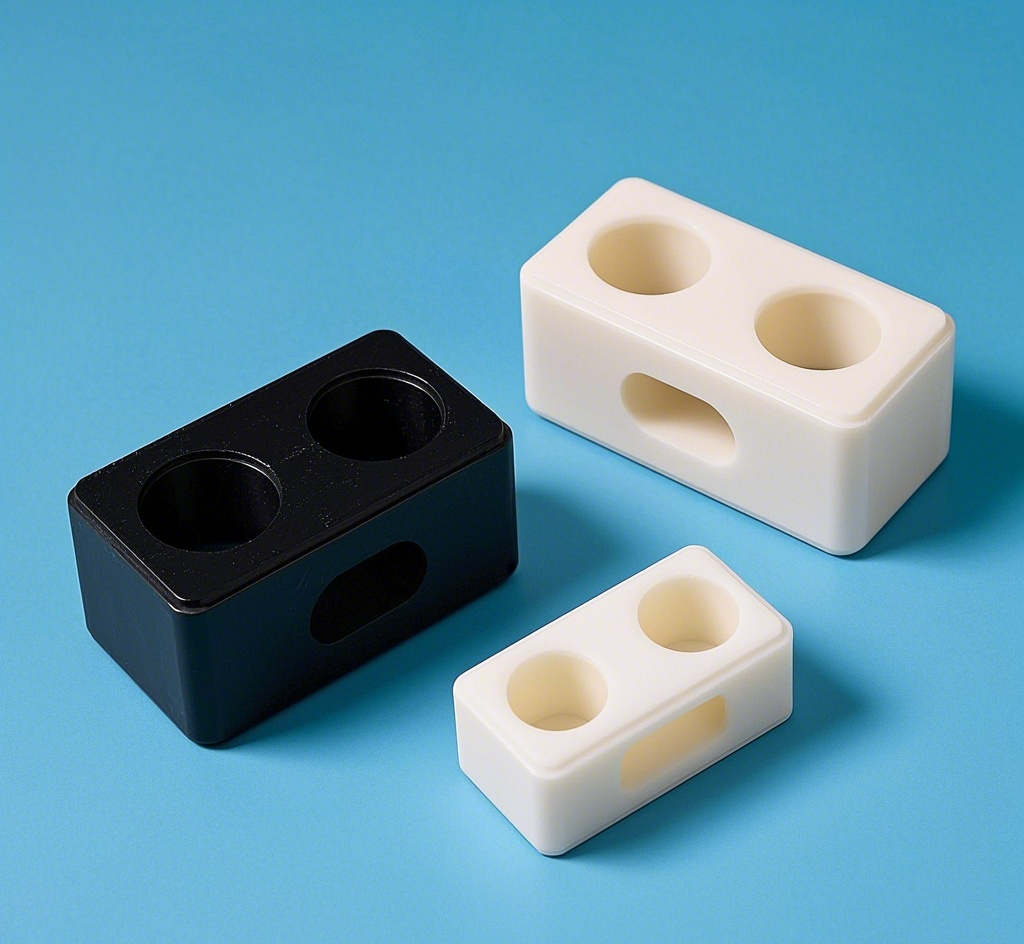

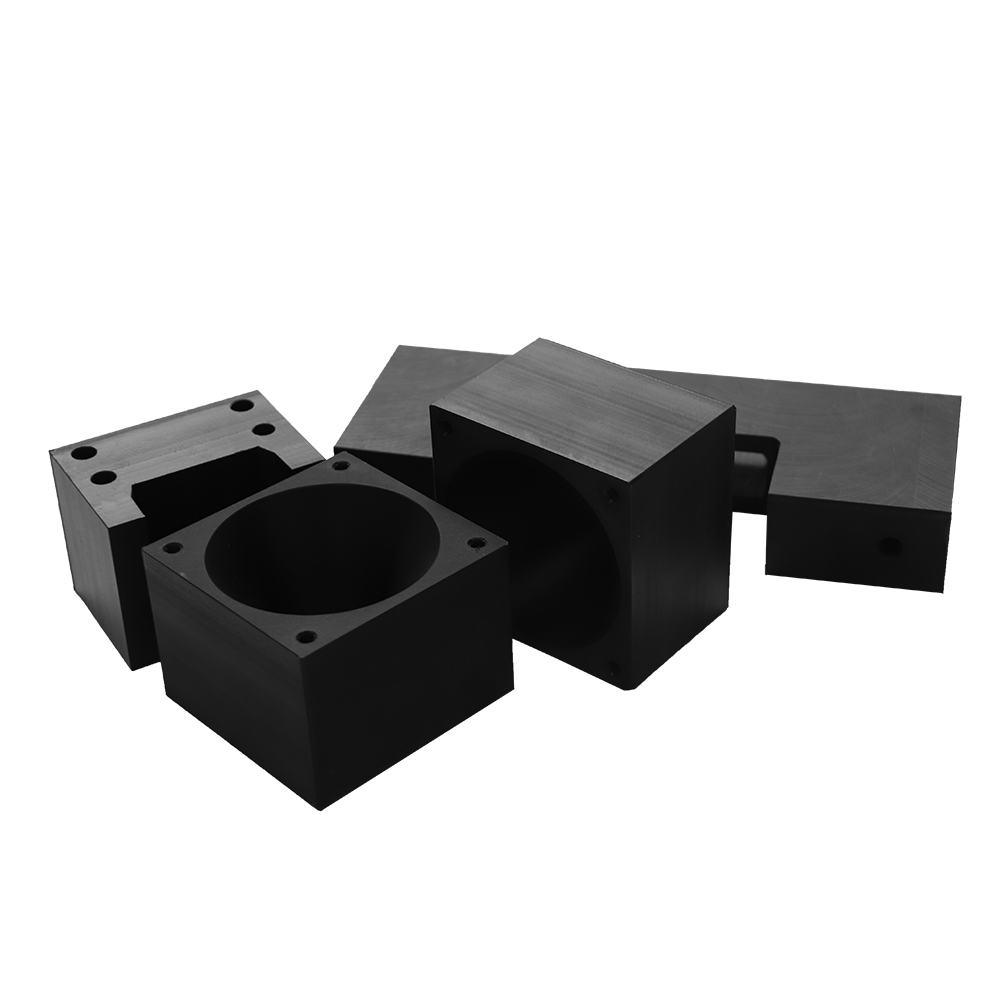

POM machined parts exhibit exceptional comprehensive properties: high mechanical strength, great stiffness, and good creep resistance; low friction coefficient and excellent wear resistance suit long-term sliding applications; outstanding dimensional stability and low water absorption ensure precise tolerances; good resistance to chemicals, especially hydrocarbons and alcohols; and a relatively broad operating temperature range (-40℃ to 100℃). They also provide excellent electrical insulation and fatigue resistance, maintaining performance under repeated stress. The material machines easily, yielding smooth surfaces, and can be modified for enhanced UV resistance or conductivity.

POM machined parts are widely used in precision machinery and automation. In the automotive industry, they serve as fuel system components, window regulator gears, and seatbelt parts requiring wear resistance. In precision instruments, they function as gear transmission systems, measuring instrument guides, and camera adjustment rings. Household appliances utilize them in gearboxes, washing machine agitators, and printer drive mechanisms for quiet operation. Additionally, they are extensively used in medical devices (e.g., nebulizer valves), sports equipment (e.g., fishing reel gears), and fluid control systems (e.g., valve plugs), meeting various dynamic functional needs with high precision, wear resistance, and self-lubrication.