- By Admin

- 德州美润耐磨材料有限公司

-

Construct Ion

-

0 Comments

- Blog

- 389

Ultra-High Molecular Weight Polyethylene Board: An Introduction

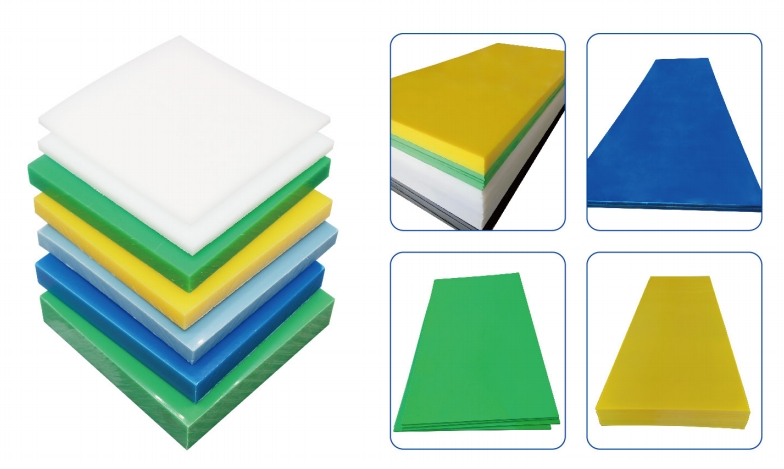

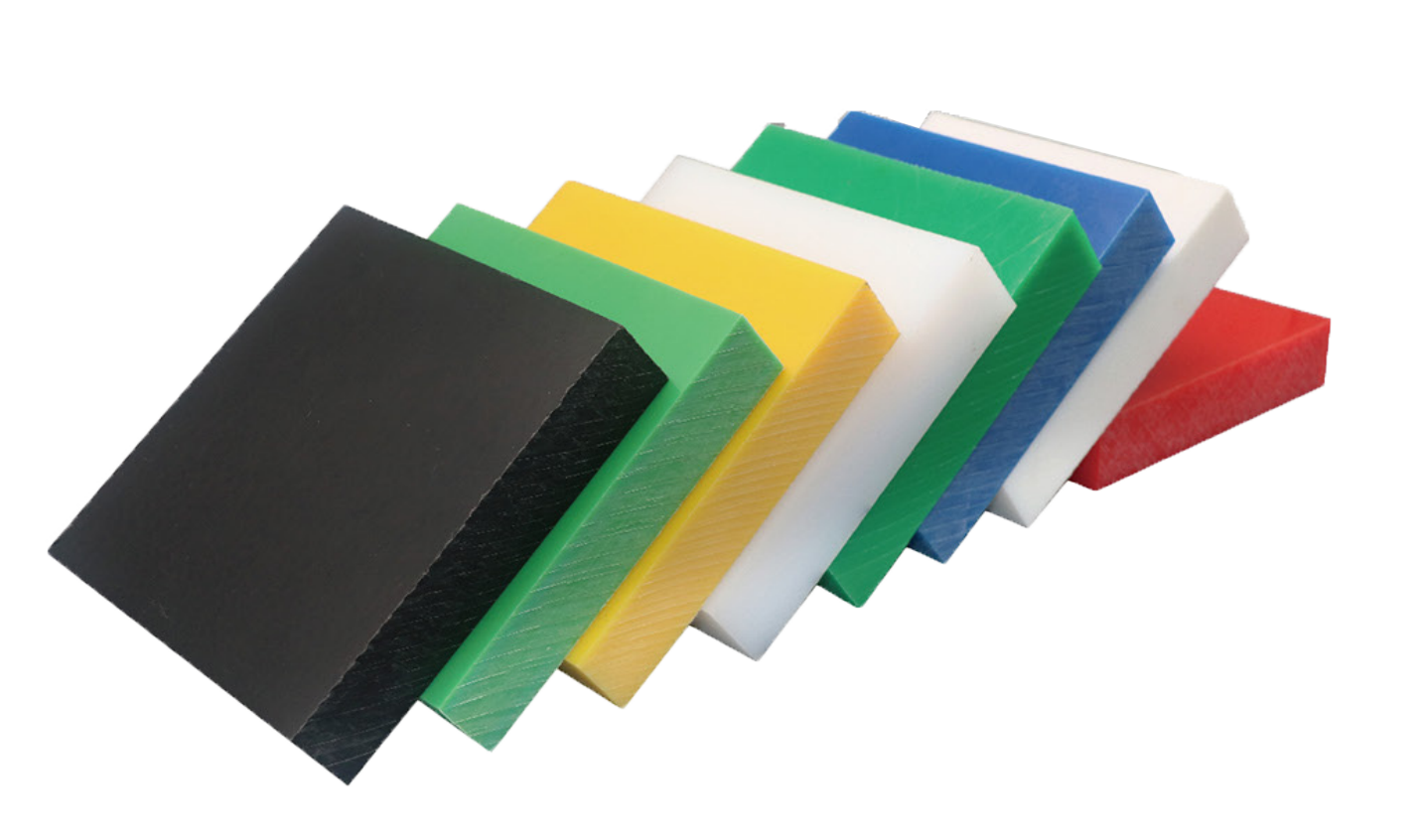

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a type of thermoplastic polymer known for its exceptional strength, durability, and low friction properties. Due to its remarkable characteristics, UHMWPE has become an indispensable material in various industrial applications. This article aims to explore the features, benefits, and application scenarios of UHMWPE boards to better understand their versatility and significance in modern manufacturing and technology.

What is UHMWPE?

UHMWPE, or Ultra-High Molecular Weight Polyethylene, is a polymer made up of long chains of ethylene molecules. With molecular weights typically exceeding 3 million g/mol, UHMWPE stands out from regular polyethylene, which has a much lower molecular weight. The unique structure of UHMWPE gives it a combination of superior mechanical, chemical, and thermal properties, which makes it ideal for demanding industrial and medical applications.

The molecular structure of UHMWPE contributes to its outstanding wear resistance, low coefficient of friction, impact strength, and chemical stability. It is also highly resistant to abrasion, making it a favored material in industries that require high durability and wear resistance. UHMWPE is also chemically inert and resistant to many acids, alkalis, and solvents.

Key Features of UHMWPE Boards

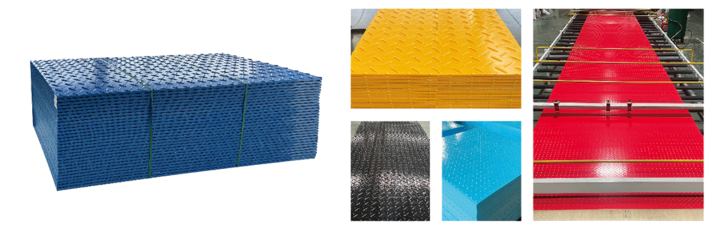

1. **High Durability**: UHMWPE boards exhibit exceptional durability under extreme conditions. This includes resistance to wear and tear, which makes them an ideal choice for high-friction environments.

2. **Low Friction**: Due to its low coefficient of friction, UHMWPE is widely used as a material for sliding and conveyor systems, reducing the wear on machinery parts.

3. **Impact Resistance**: UHMWPE boards can absorb high impacts without significant deformation or damage, making them a preferred material in mining, construction, and material handling systems.

4. **Chemical Resistance**: UHMWPE is resistant to a wide range of chemicals, making it useful in environments where contact with harsh chemicals is common.

5. **Lightweight**: Despite its high durability, UHMWPE boards are relatively light compared to metals, making them easy to handle and install.

6. **Environmental Resistance**: UHMWPE performs well in extreme temperatures, both high and low, making it versatile in diverse environments.

7. **Biocompatibility**: UHMWPE is often used in medical devices, particularly in implants and prosthetics, due to its biocompatibility and ability to withstand repetitive stress.

Applications of UHMWPE Boards

1. **Medical and Healthcare**: One of the most notable uses of UHMWPE is in the medical field, particularly in joint replacements and prosthetics. UHMWPE is commonly used in hip and knee implants due to its ability to withstand high stress, reduce friction, and promote longer-lasting implants.

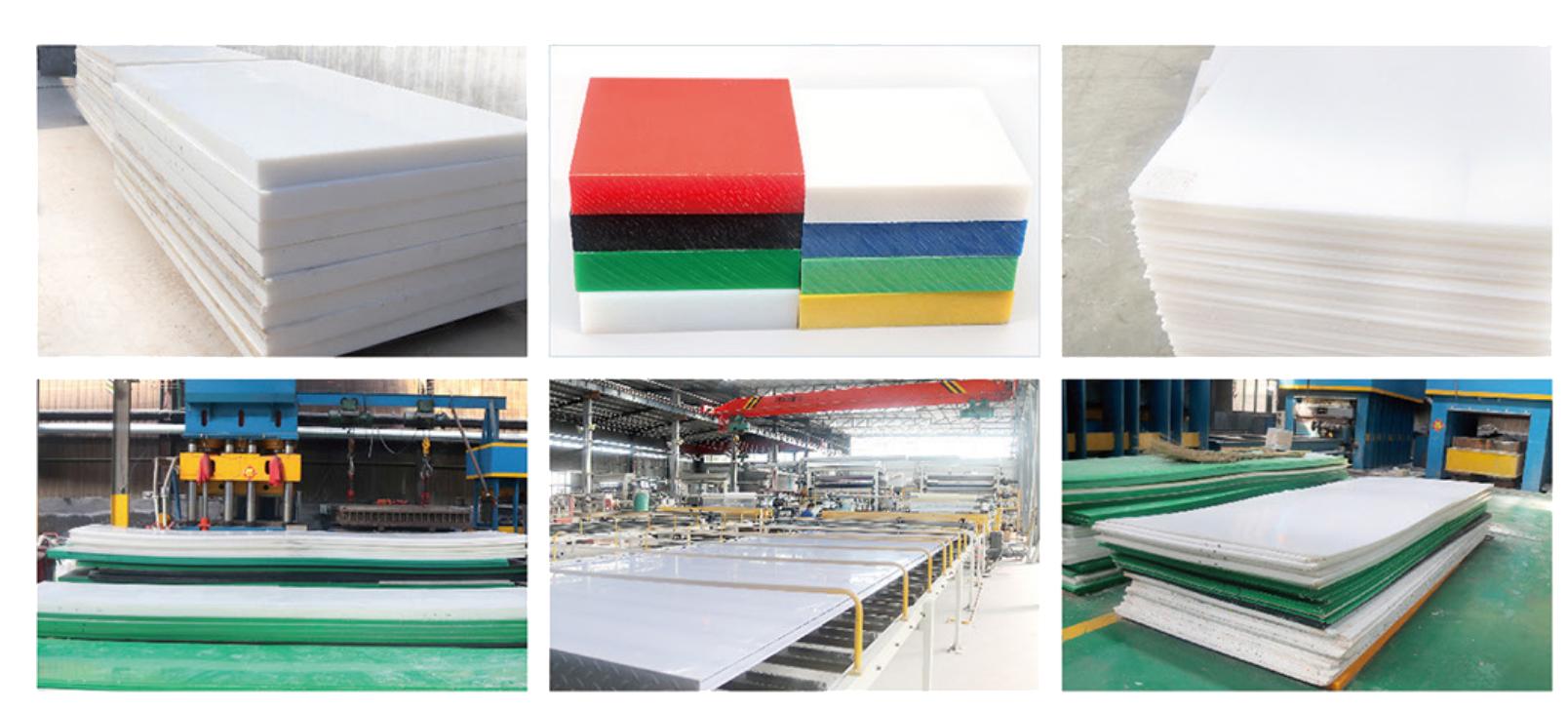

2. **Material Handling and Conveying Systems**: UHMWPE boards are often used in conveyor systems, chutes, and hoppers to reduce friction and extend the life of the equipment. The material’s ability to withstand abrasion and its self-lubricating properties make it ideal for these applications.

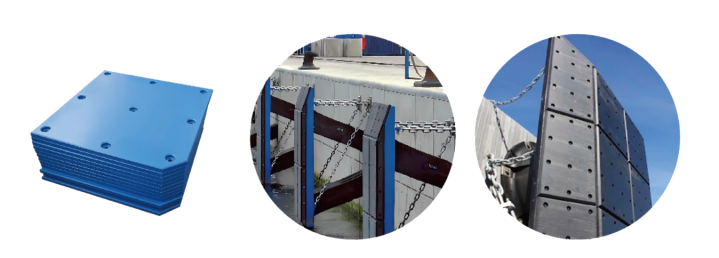

3. **Mining and Bulk Material Handling**: UHMWPE is used extensively in mining operations, particularly in the construction of liners for hoppers, chutes, and bunkers. The boards can handle the harsh impact of materials like ores and coal, reducing maintenance needs and improving productivity.

4. **Food Processing Industry**: UHMWPE’s non-toxic and food-safe properties make it suitable for the food processing industry. It is commonly used in the manufacturing of equipment like conveyor belts and cutting boards.

5. **Automotive and Aerospace**: In the automotive and aerospace industries, UHMWPE boards are used in systems where lightweight and durable materials are needed, such as in protective coatings and components that are exposed to extreme mechanical wear.

6. **Recreational and Sporting Goods**: The material’s low friction and impact resistance properties are also valuable in applications like skis, snowboards, and other sporting equipment where durability is key.

Conclusion

Ultra-High Molecular Weight Polyethylene boards are a vital component in many industries due to their exceptional physical properties. Their ability to resist wear, friction, and impact, coupled with their chemical stability, makes them a versatile material for applications ranging from medical devices to industrial equipment. With continuous advancements in material science, UHMWPE boards will undoubtedly continue to play an essential role in various sectors, driving innovation and efficiency across numerous industries.