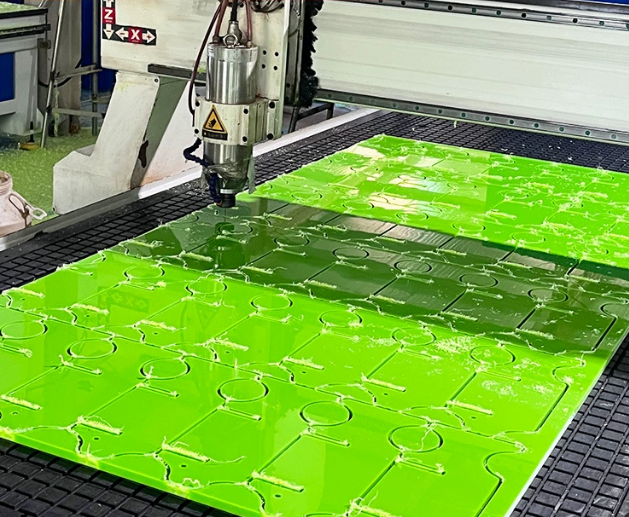

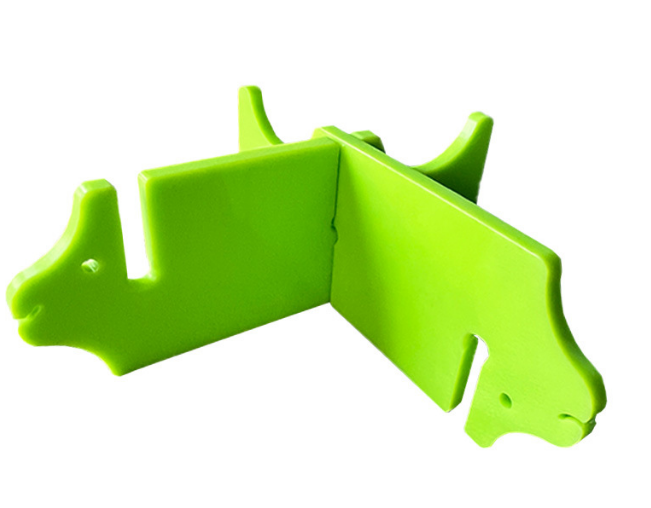

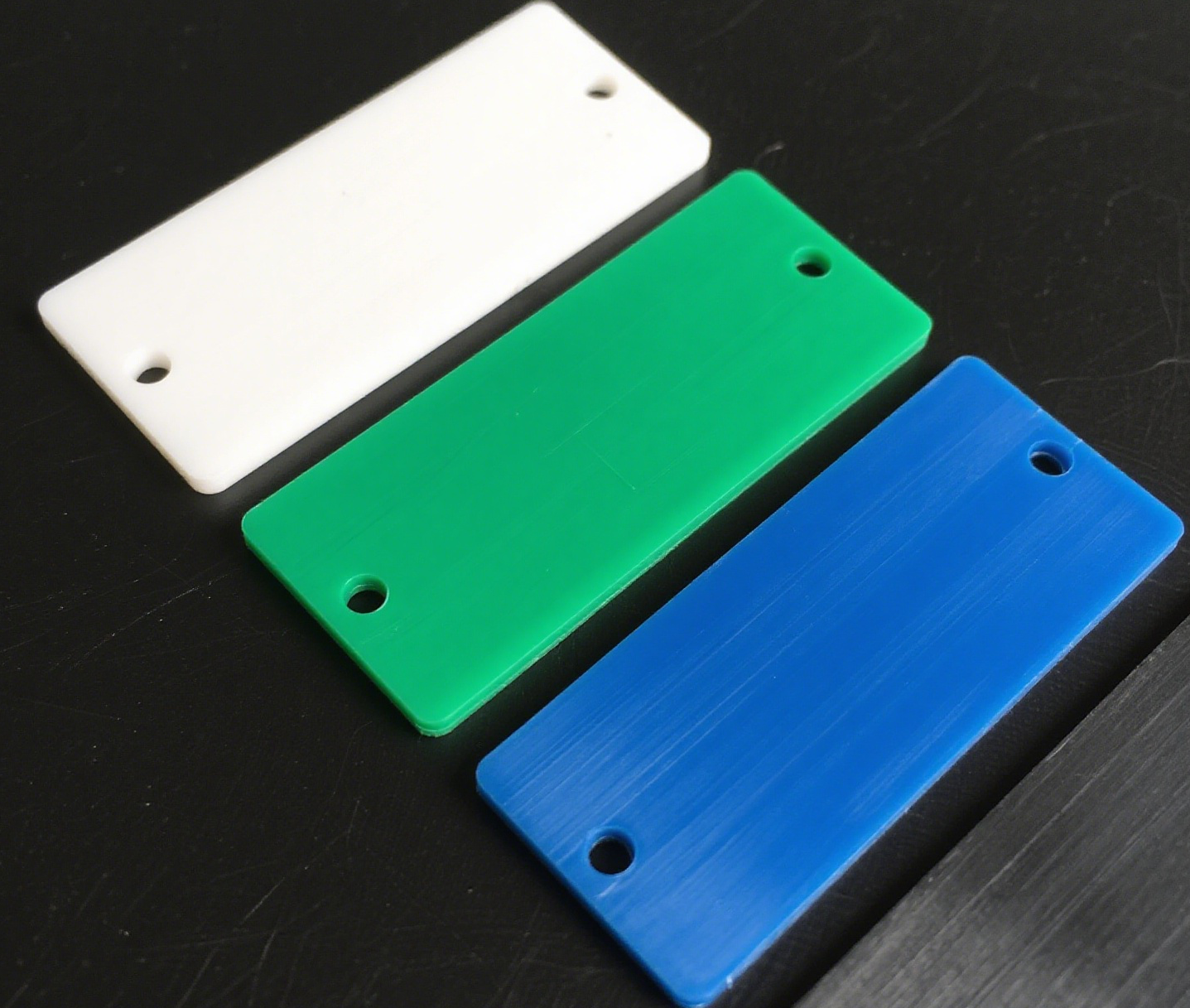

HDPE and PP special-shaped parts offer several key properties: HDPE exhibits high mechanical strength and impact resistance, retaining toughness at low temperatures, while PP provides better heat resistance and stress crack resistance. Both materials show strong resistance to acids, alkalis, and various chemical solvents, ensuring long service life. They are lightweight, electrically insulating, and exhibit low water absorption and high dimensional stability. Non-toxic and odorless, some grades comply with food contact standards. Modifications can further improve weatherability, conductivity, or wear resistance. Their processing flexibility supports the production of hollow, thin-walled, or complex geometries as integrated parts, reducing assembly complexity and cost.

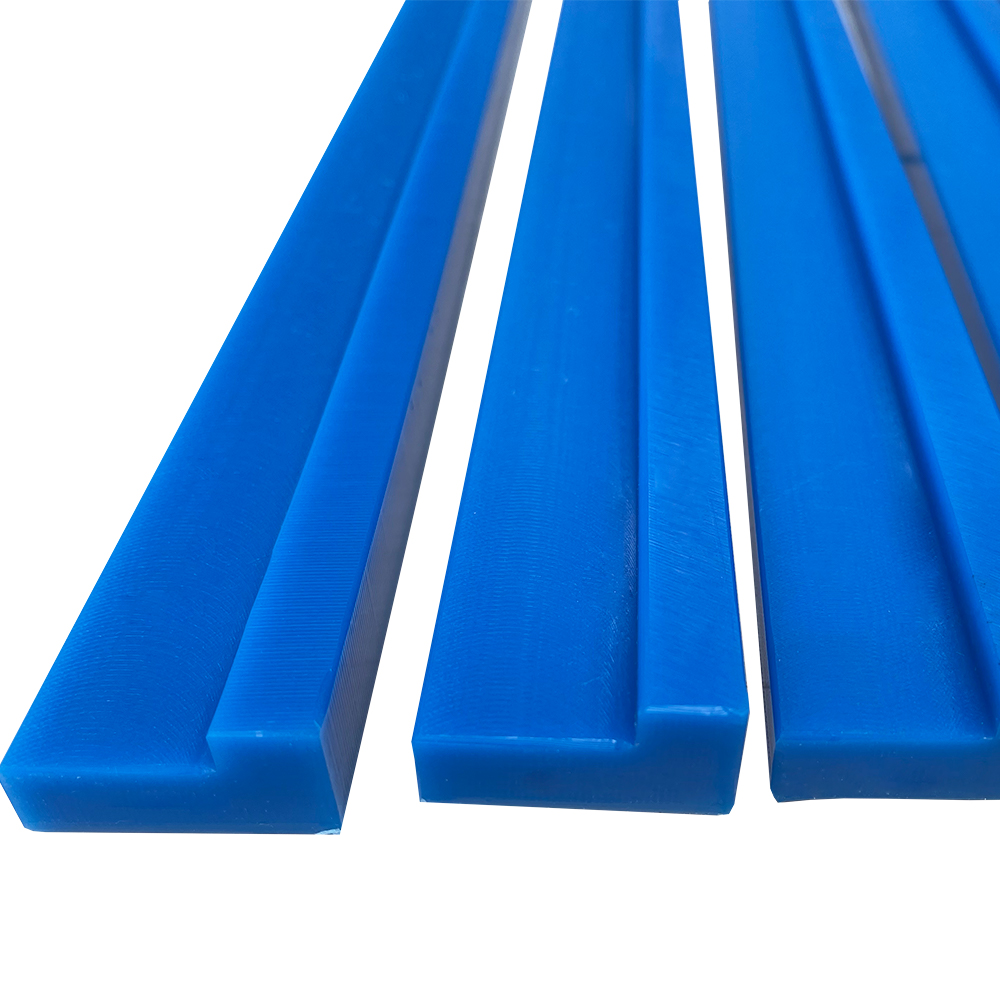

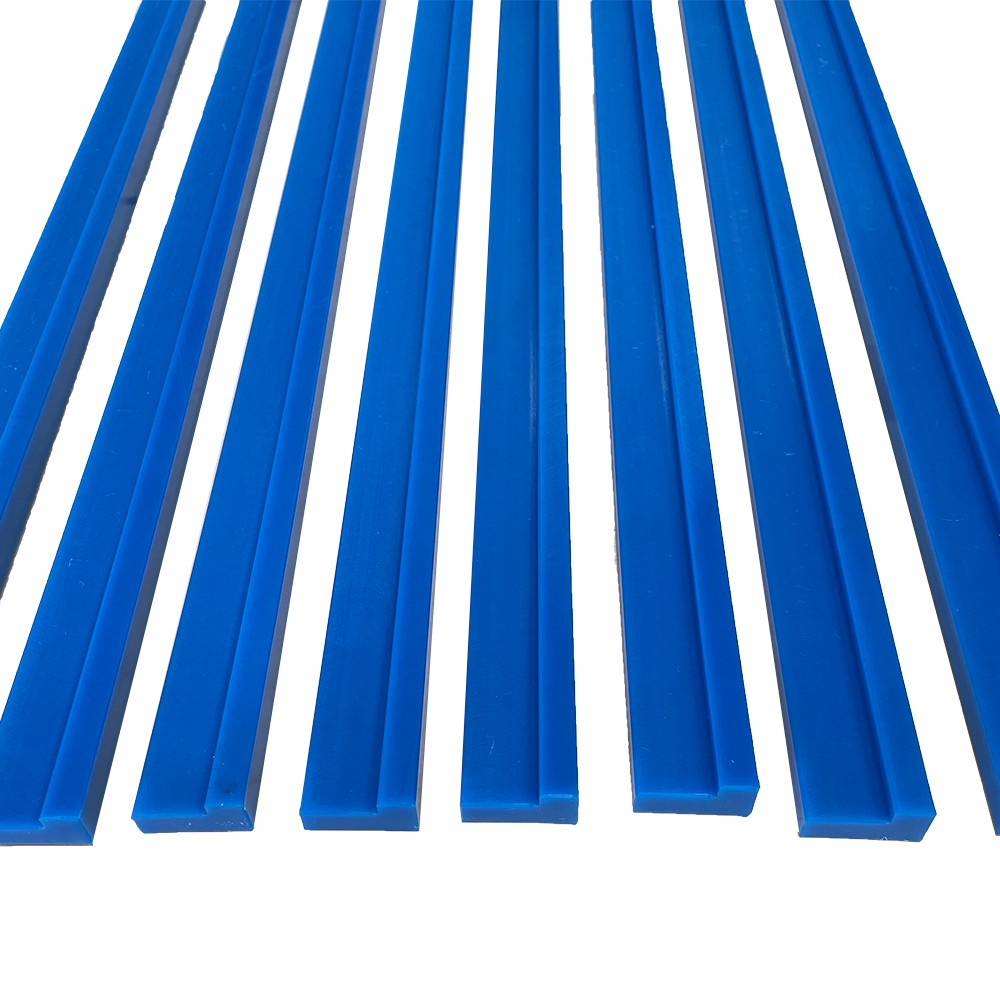

HDPE and PP special-shaped parts are widely used across multiple sectors. In chemical and environmental industries, they serve as tank liners, ventilation ducts, and wastewater treatment components due to their corrosion resistance. In water supply and drainage systems, they are used for valve wells, pipe fittings, and water tank parts, offering safety and non-toxicity. The logistics industry utilizes them for pallets, conveyor guides, and shelf spacers, benefiting from their wear resistance and light weight. In automotive applications, they are found in battery cases and ventilation ducts for their heat tolerance. Additional uses include food machinery, home appliances, agricultural irrigation systems, and construction, such as food conveyor baffles, washing machine tub parts, and greenhouse supports, meeting needs for cost-effective, lightweight, and durable components.