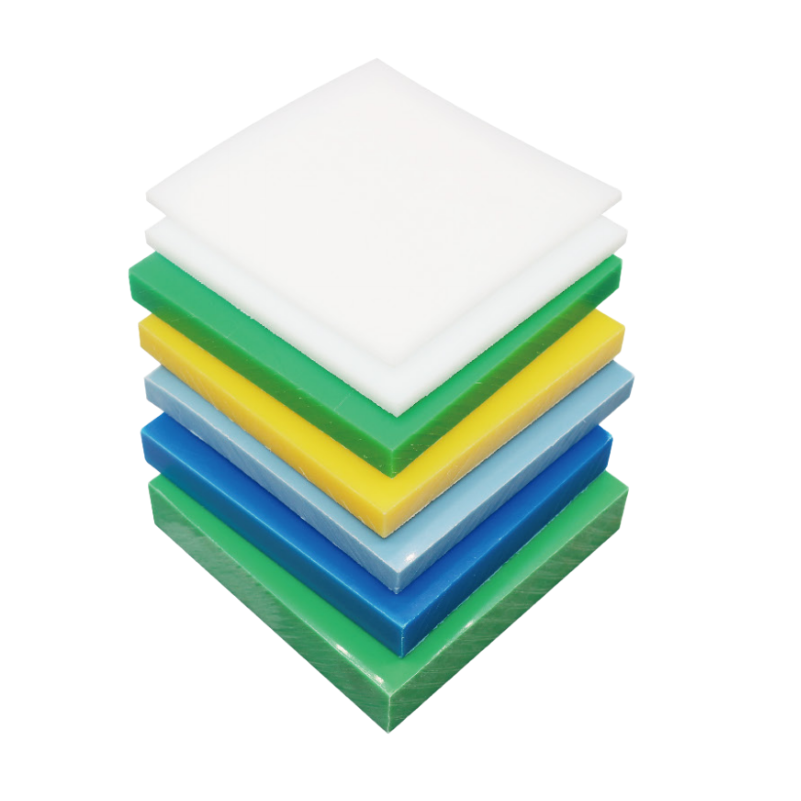

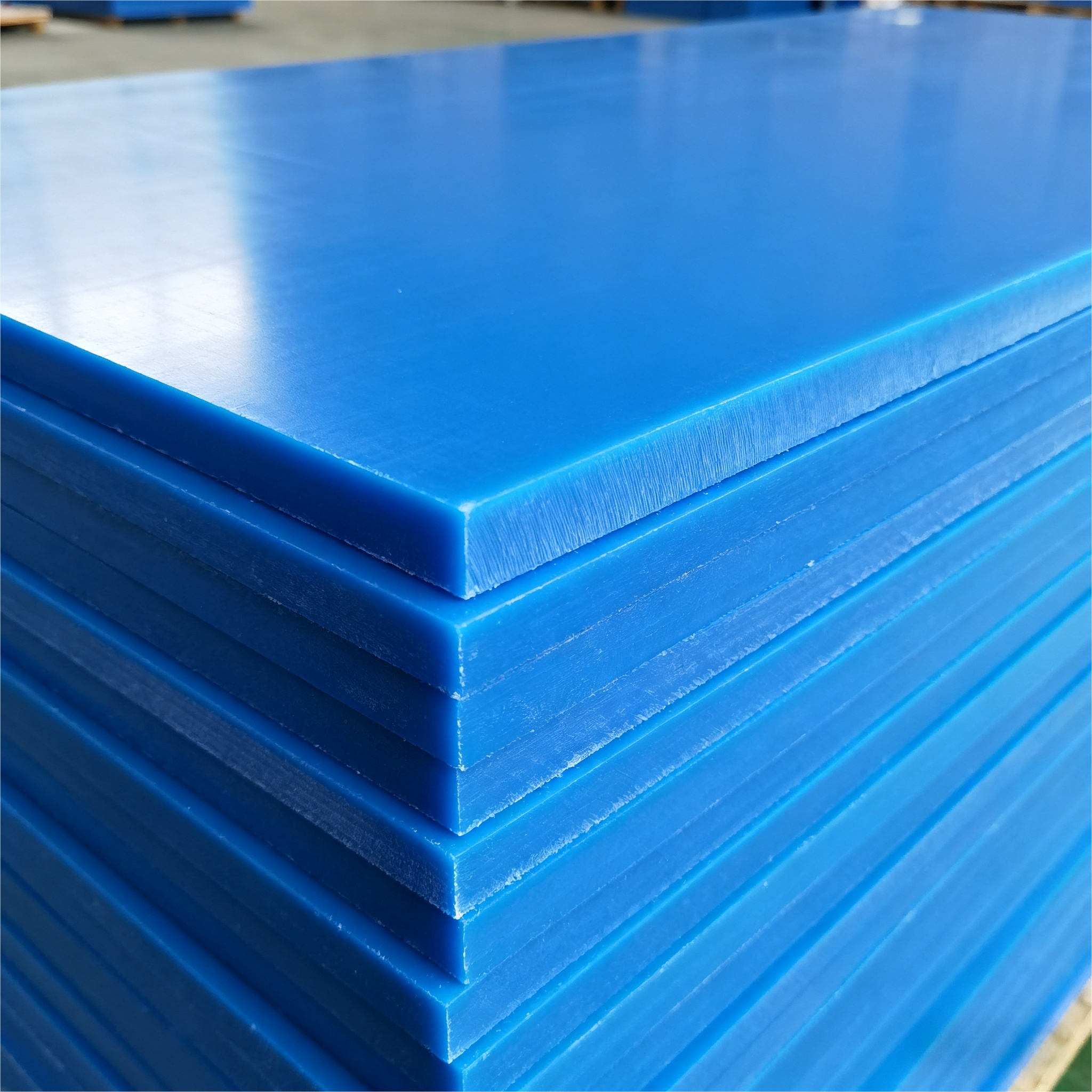

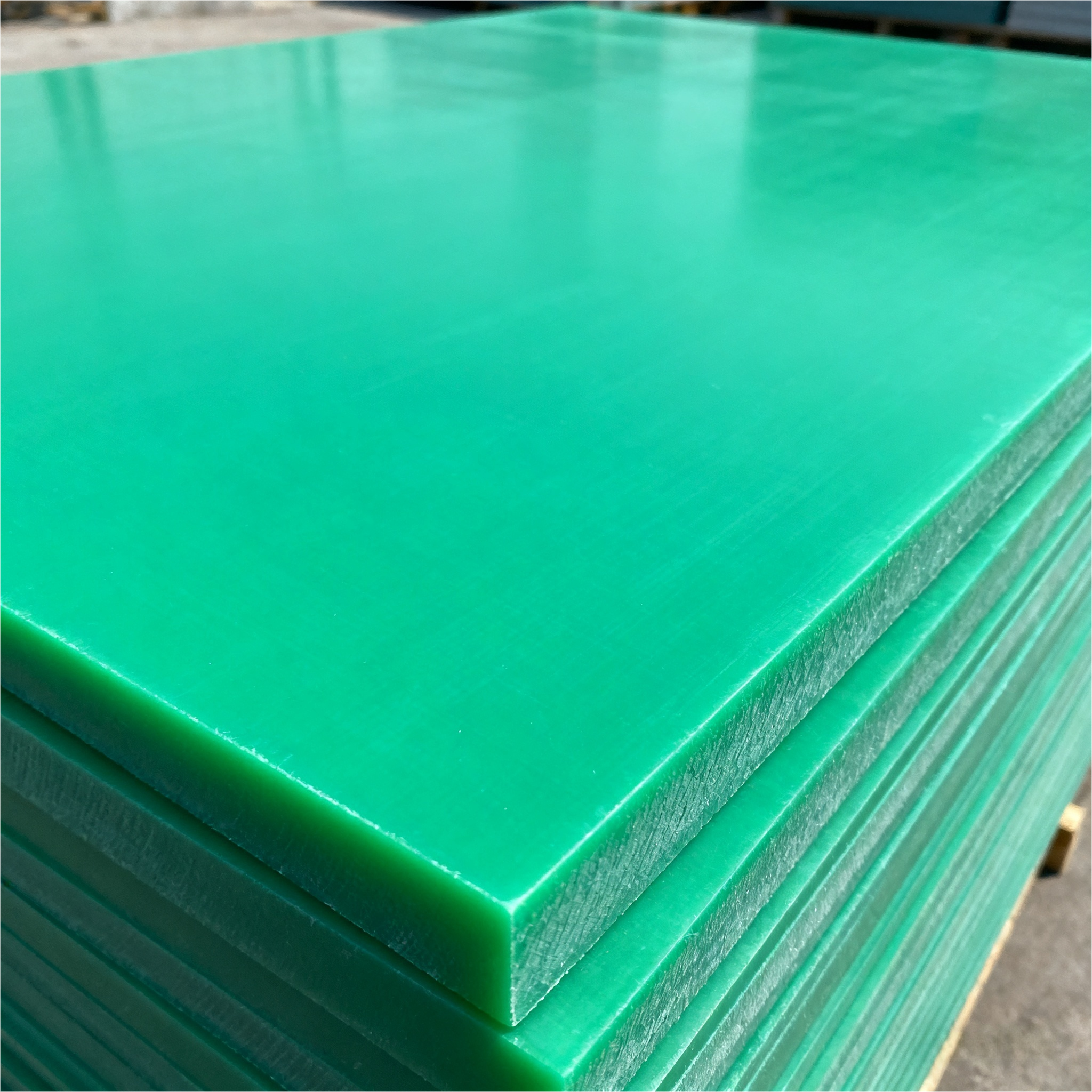

Extreme Wear Resistance: Its wear rate is 1/8 that of ordinary steel and 1/4 that of nylon. The component replacement cycle is extended by 3-5 times, significantly reducing maintenance costs.

Weather Resistance & Impact Resistance: Works stably at temperatures ranging from -269℃ to 80℃, with no risk of brittleness in low-temperature environments, suitable for outdoor equipment in frigid regions or cold chain scenarios.

Low Friction & Easy Maintenance: Has a friction coefficient of 0.05-0.1 (close to that of polytetrafluoroethylene) and inherent self-lubricating property, eliminating the need for frequent lubricant addition and reducing equipment operation resistance.

Corrosion Resistance & Safety: Resistant to most inorganic acids, alkalis and organic solvents, non-toxic and odorless, and compliant with the GB 4806.7 food contact standard, meeting both industrial corrosion resistance and daily life safety requirements.

Applications

Industrial Wear-Resistant Liner Category:

Energy/Mining: Chute liners and silo liners for the coal/power industry, liners for mining crushing equipment, and hopper liners for grain storage (anti-clogging and wear-resistant);

Chemical/Environmental Protection: Linings for chemical reaction kettles and scrapers for sewage treatment equipment (acid and alkali resistant, suitable for harsh working conditions);

Transmission & Conveyance Category:

Mechanical Transmission: Chain guides and curved rails (low friction to reduce wear), roller bushings and drum liners for conveying equipment (suitable for high-load conveyance scenarios);

Cold Chain Conveyance: Shelf liners for cold storage and conveying rails for frozen food (low-temperature resistant and non-deformable);

Daily Life and Special Scenario Category:

Daily Life: Household/commercial cutting boards (cutting-resistant and easy to clean, compliant with food standards), slide panels for children's amusement facilities, and wear-resistant components for outdoor fitness equipment (durable with no risk of sharp debris).

Engineering Protection: Pad liners for engineering machinery support wheels, dock fenders, and anti-collision plates for port machinery (wear-resistant and impact-resistant, protecting equipment structure).