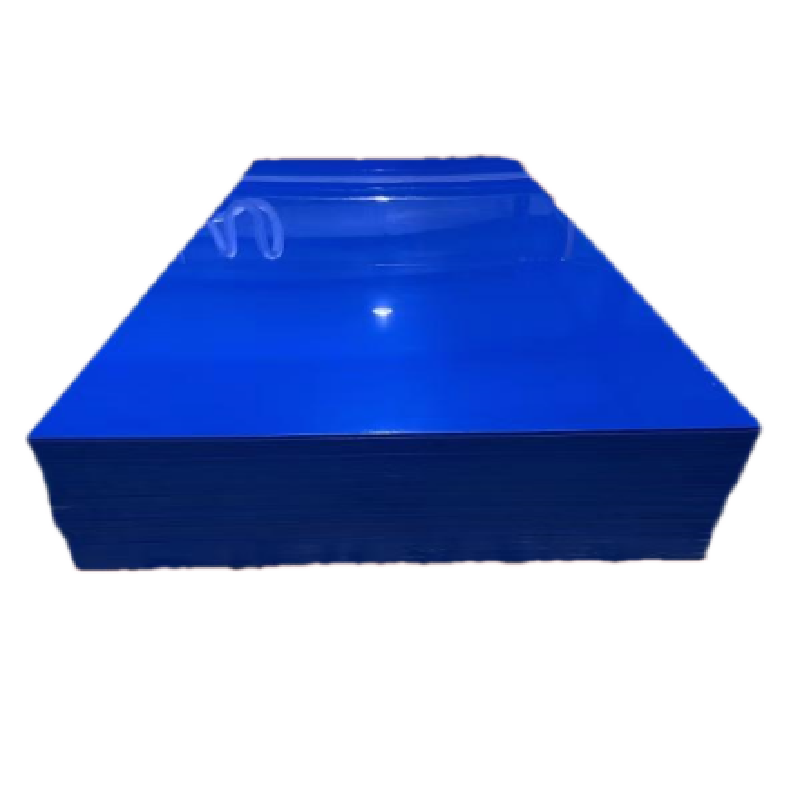

Outstanding Heat Resistance: Can be used stably for a long time at around 100℃, and can withstand high temperatures of 120℃ for a short period (such as scenarios in contact with boiling water or hot drinks); its softening temperature is about 110℃, making it suitable for medium-low temperature heating environments.

Fatigue Resistance & Corrosion Resistance: Known as "hundred-fold adhesive" due to its excellent bending fatigue resistance, it is not easy to break after repeated bending, making it suitable for components with high-frequency deformation; at the same time, it is resistant to most dilute acids (e.g., dilute hydrochloric acid) and alkalis (e.g., sodium hydroxide solution), with strong chemical stability.

Excellent Processability: Can be flexibly subjected to injection molding, welding, cutting and thermoforming. It not only meets mass production needs (e.g., home appliance casings) but also adapts to customized component processing, with high production efficiency.

Water Storage & Conveyance Field: Used to make household water storage tanks, industrial circulating water tanks (resistant to normal-temperature water corrosion), and low-pressure chemical conveying pipelines (suitable for weakly corrosive media).

Automotive & Home Appliance Field: Applied in automotive bumpers, instrument panel brackets (light weight helps reduce energy consumption), and home appliance casings (e.g., inner tubs of washing machines, outer casings of air conditioners, resistant to temperature differences and daily use wear).