- By Admin

- 德州美润耐磨材料有限公司

-

Construct Ion

-

0 Comments

- Blog

- 298

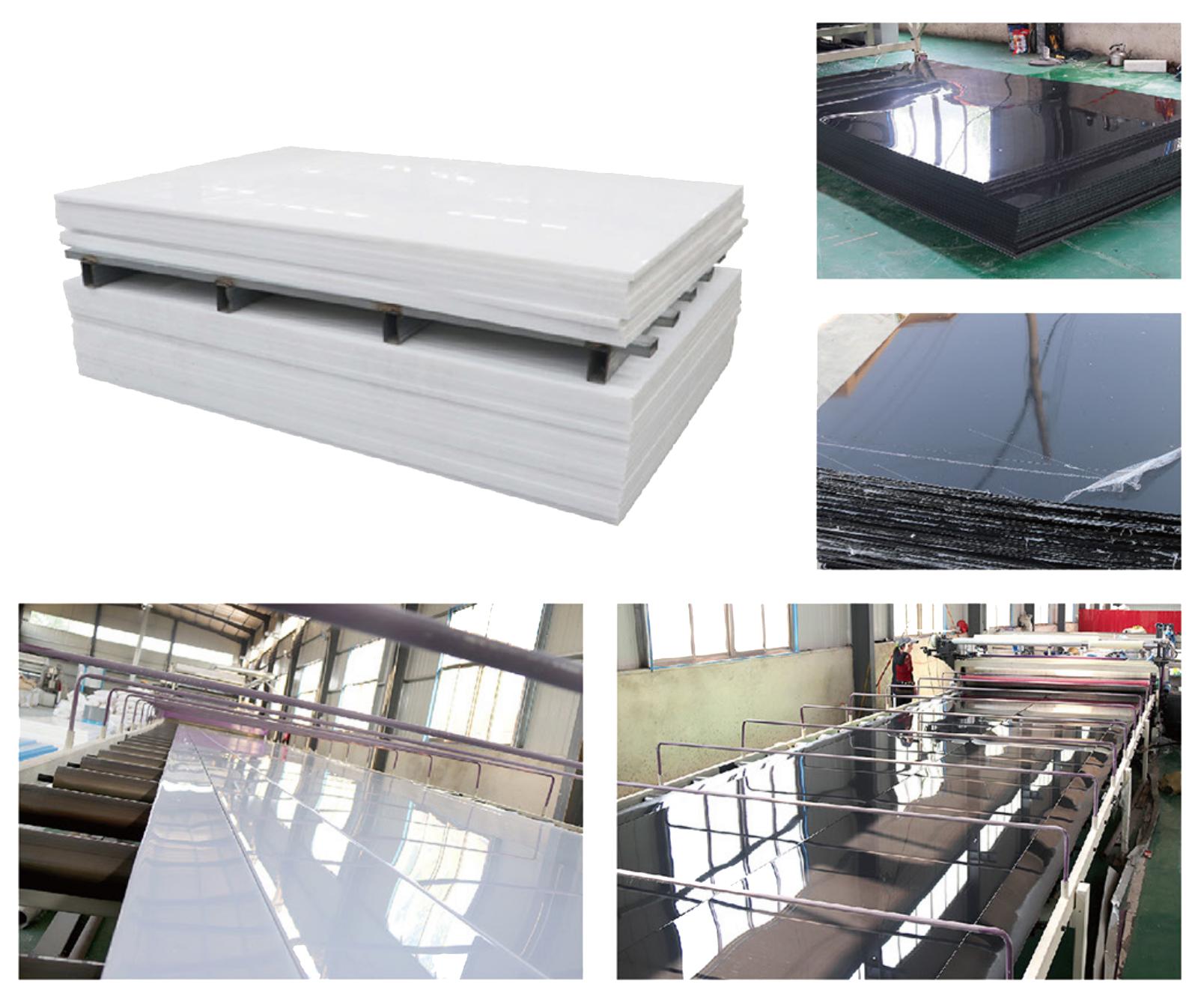

Poly Tetra Fluoro Ethylene (PTFE) Boards: An In-Depth Overview

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance thermoplastic polymer with outstanding chemical resistance, electrical insulation properties, and a unique non-stick surface. PTFE boards, made from this versatile material, are widely used in various industries for applications requiring high temperature resistance, low friction, and durable performance. In this article, we will explore the properties, benefits, and various application scenarios of PTFE boards to highlight their significance in modern engineering and manufacturing.

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a high-performance thermoplastic polymer with outstanding chemical resistance, electrical insulation properties, and a unique non-stick surface. PTFE boards, made from this versatile material, are widely used in various industries for applications requiring high temperature resistance, low friction, and durable performance. In this article, we will explore the properties, benefits, and various application scenarios of PTFE boards to highlight their significance in modern engineering and manufacturing.

What is PTFE?

PTFE, or Polytetrafluoroethylene, is a synthetic fluoropolymer of tetrafluoroethylene. It is a white, waxy solid that is non-reactive and has an extremely high melting point. PTFE is known for its non-stick properties and is used in a variety of applications where resistance to high temperatures, corrosion, and electrical conductivity is required.

PTFE is made by polymerizing tetrafluoroethylene, a highly reactive gas. The result is a polymer that exhibits remarkable resistance to heat, chemical reactions, and friction. It is also an excellent electrical insulator, making it ideal for applications in the electrical and electronics industries.

Key Features of PTFE Boards

1.**Exceptional Chemical Resistance**: PTFE is highly resistant to most chemicals, acids, and bases. This makes it ideal for applications in the chemical industry, particularly in environments where other materials may degrade.

2. **High-Temperature Stability**: PTFE boards can withstand temperatures ranging from -200°C to 260°C, making them suitable for use in high-temperature applications such as furnace linings and heat exchangers.

3. **Low Friction**: PTFE is renowned for its low coefficient of friction, which reduces wear and tear on moving parts and minimizes energy consumption in mechanical systems.

4. **Electrical Insulation**: Due to its excellent insulating properties, PTFE is widely used in the electrical industry to insulate wiring, cables, and other components.

5. **Non-Stick Properties**: PTFE’s ability to repel water and other substances makes it ideal for applications requiring non-stick surfaces, such as in food processing equipment and lubricants.

6. **Biocompatibility**: PTFE is biocompatible and is used in medical devices, including implants and surgical instruments, due to its resistance to bacterial growth and its ability to withstand prolonged exposure to bodily fluids.

Applications of PTFE Boards

1. **Chemical Processing Industry**: PTFE boards are extensively used in chemical processing equipment such as valves, seals, gaskets, and pipes. Their resistance to acids, alkalis, and solvents makes them ideal for handling corrosive materials in chemical plants.

2. **Electrical and Electronics Industry**: PTFE is a top choice for insulating electrical components, including wiring, cables, and circuit boards. Its low dielectric constant and excellent electrical insulation properties ensure the safe operation of electrical equipment.

3. **Food Processing**: In the food industry, PTFE boards are used for their non-stick properties and ability to withstand high temperatures. They are commonly found in equipment such as conveyor belts, frying pans, and baking sheets, where non-stick, durable, and heat-resistant surfaces are needed.

4. **Aerospace and Automotive**: The aerospace and automotive industries use PTFE boards for parts such as bearings, bushings, and seals. Its low friction and ability to withstand extreme temperatures make PTFE an essential material for high-performance applications in these sectors.

5. **Medical Field**: PTFE is used in various medical applications, including implants, catheters, and surgical instruments. Its biocompatibility, non-reactivity, and resistance to bacterial growth make it a safe choice for medical devices that come in contact with the human body.

6. **Manufacturing and Engineering**: PTFE boards are widely used as wear-resistant liners and coatings in industrial machinery, such as in conveyors and chutes, to reduce friction and prevent material build-up.

Conclusion

Polytetrafluoroethylene (PTFE) boards are indispensable in a wide range of industries due to their remarkable properties, including chemical resistance, high-temperature stability, and low friction. Whether used in chemical processing, electronics, food production, or medical devices, PTFE continues to be a material of choice for applications requiring durability, reliability, and superior performance. As industries continue to innovate, the demand for PTFE boards will likely grow, driving further advancements in material technology and applications.