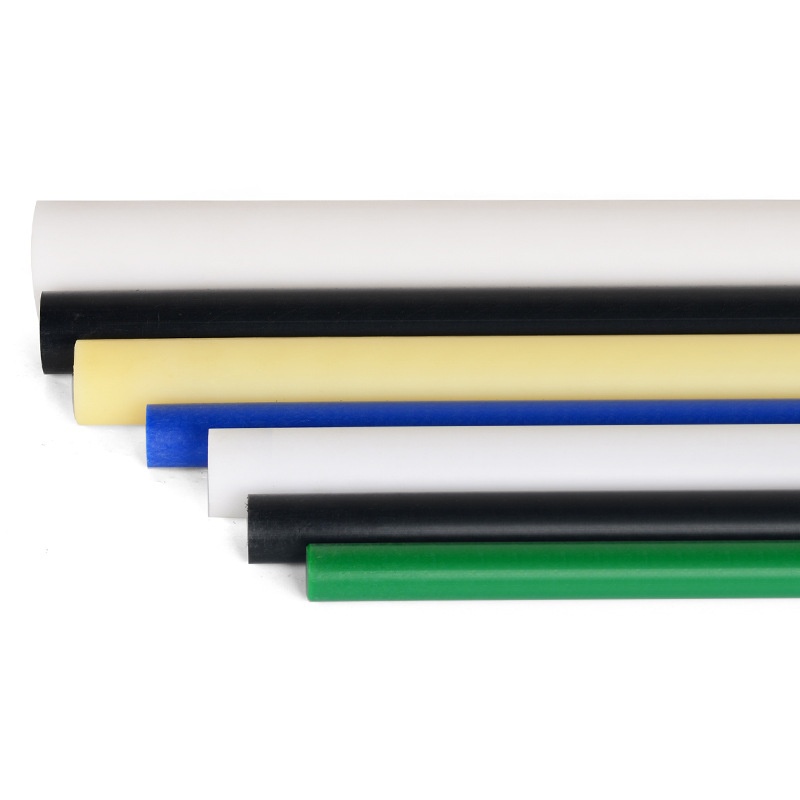

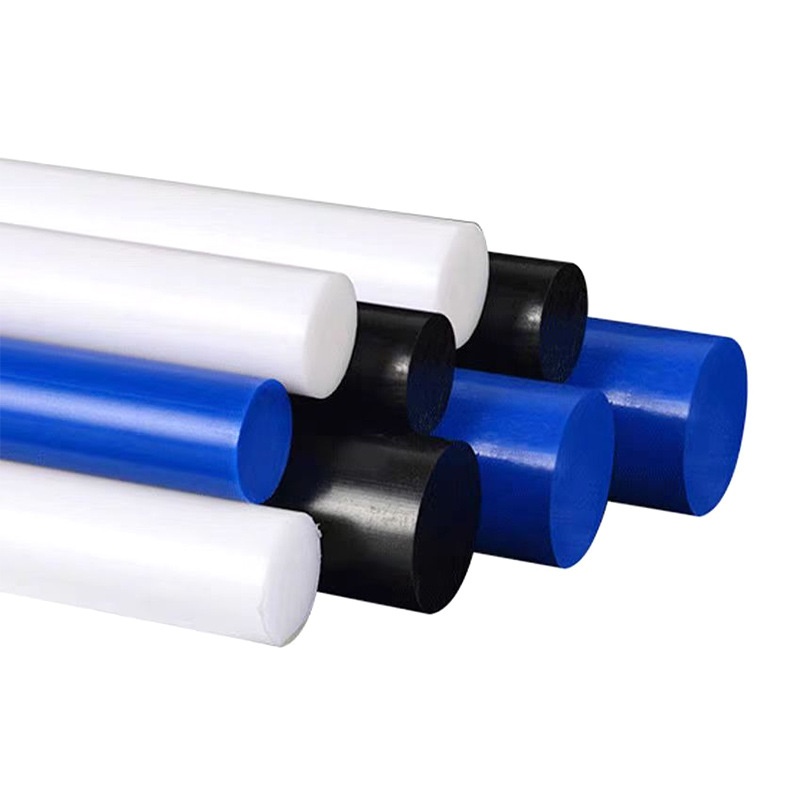

MC nylon rods offer exceptional mechanical strength, with improved tensile, flexural, and impact resistance compared to standard PA nylon rods, enabling them to withstand greater loads. They also exhibit excellent wear resistance and high surface hardness, minimizing wear even after extended use.Process ensures high dimensional accuracy, enabling precise control of rod dimensions and reducing subsequent processing requirements. MC nylon rods exhibit excellent aging resistance, maintaining performance even after prolonged exposure to air or sunlight. They also offer excellent corrosion and oil resistance, making them suitable for a variety of challenging operating conditions. PA nylon possesses excellent mechanical properties, including high tensile strength, impact strength, and fatigue resistance, enabling them to withstand prolonged dynamic loads. Its excellent wear resistance and low coefficient of friction enable stable operation without lubrication. MC nylon also offers excellent oil resistance, good tolerance to various lubricants, and low swelling. It is also chemically resistant, stable in mild acids, bases, and most organic solvents. Its excellent machinability makes it easy to cut, drill, weld, and perform other processing operations.

MC nylon is commonly used in bearings, bushings, and gears in heavy machinery; scrapers and liners in mining equipment; roller tracks and guide components in the metallurgical industry; and pulleys and wear bushings in port machinery. It demonstrates exceptional durability under demanding conditions of high loads and severe wear.PA nylon is suitable for gears, bushings, and washers in machinery manufacturing; engine components and chassis connectors in the automotive industry; insulating brackets and terminal blocks in electrical and electronic applications; and textile machinery accessories and yarn guides in the textile industry. It has a wide range of applications across various industrial sectors.